John Barker

John Barker

barkerknives.com

Georgia, USA

My interest in knives started as a child with my father’s old Case pocket knives. My dad always had a knife in his pocket and he taught me to always have one too. I found myself collecting more and more knives over the years.

Then, one day, my friend Will Dutton asked me to go to the Blade Show with him. Will had just started making knives a few months earlier. The Blade Show really sparked my interest in making knives and I built my first knife in August 2006 at Will’s shop. From then on, I knew I had found something special in knifemaking.

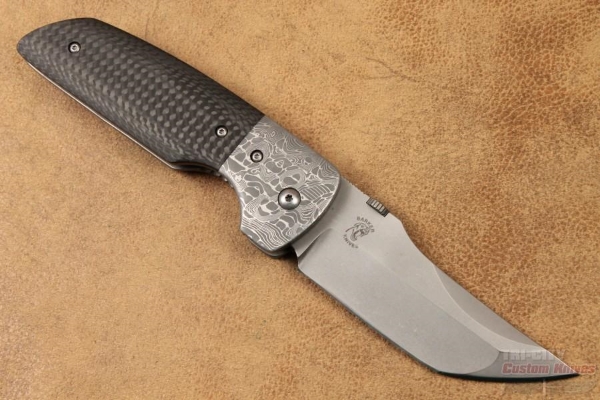

I like to build custom fixed blade knives that have a tactical flare to them. I make fighters, hunters and utility designs using the finest steels available in Crucible’s CPM line of knife steels. I like to use CPM 154, CPM D2, CPM S30V and CPM D2. These steels employ Crucible’s Particle Metallugy technology for superior blade performance.

My knives are made for hard use. I hollow grind my blades in a unique way to make my knives as light as possible, but maintain a strong convexed cutting edge. I also taper the tang on every knife to achieve a balanced knife that seems like an extension of your hand.

I use a variety of handle material, but prefer Micarta for tactical knives and knives that will see a lot of use. The reason being that Micarta is extremely durable and has a good grippiness even when wet. I also make one off custom designs as requested.

But, be assured that each knife is custom. Custom fit for the person using them. We don’t all have the same size hand, so why should a knife be one size fits all. I make my knives based on hand size so that it will perform as an extension on your hand and be comfortable when using even for extended periods.